Although a large wheat crop is expected, there are reports of relatively poor quality in some production regions because of heavy rains during the harvest period. The wet conditions can cause sprouted wheat that can affect the falling number. A low falling number indicates high enzyme activity, most often as a result of sprout damaged wheat or flour. Too much enzyme activity affects many aspects of the breadmaking process, resulting in delays in production and losses due to poor quality finished products.

The birth and growth of a new plant is at the heart of agriculture and the cereal industry. The enzyme alpha (α) -amylase is an enzyme in cereals that plays an important role in the life of a new plant. The new plant needs sugar to grow, and the enzyme breaks down starch into sugar for the new plant to feed on in the first few days of seed germination. This ability of alpha-amylase enzyme to break down starch into sugar in cereals (and in particular in wheat) makes it just as important in breadmaking, as it plays a large role in gas production.

During breadmaking, alpha-amylase breaks the complex starch in the flour down into sugars. The yeast in the bread recipe cannot digest the starch and needs sugar as a food source. The alpha-amylase therefore provides the yeast with sugar to ferment, so that carbon dioxide gas can be produced, which makes the dough rise (Cauvain and Young, 2001).

In breadmaking, if the wheat flour does not contain enough alpha-amylase, it can have negative results, such as long proving times for dough, as well as bread with pale crust, low volume and dense crumb. This can easily be improved by adding alpha-amylase, which can be added in the form of fungal-, cereal- (usually malt) or bacterial amylase.

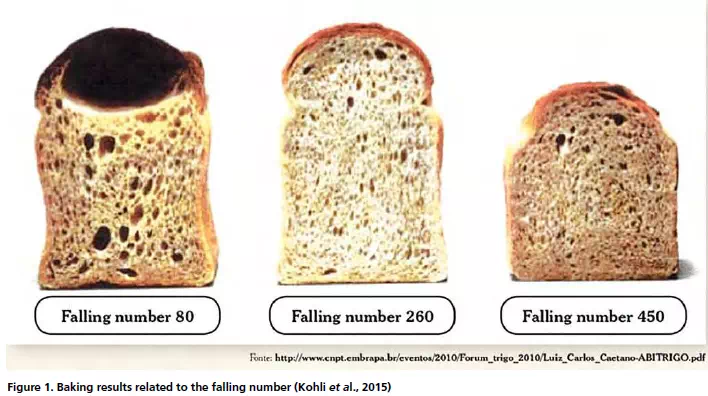

Too much enzyme activity, however, will result in too much sugar being present and not enough starch, which affects many aspects of the breadmaking process, such as dough processing, baking, slicing and the overall appearance of the bread. The flour absorbs less water and the dough is soft and sticky, which makes dough handling difficult. During the baking process, large, open holes are formed and sticky crumb, which accumulates on slicer blades. Also, the large amount of sugar present causes the crust to become too dark and appear burnt (Figure 1). The result is therefore that bread loaves are deformed, difficult to slice and have too dark crusts, all of which are unattractive to customers.

In a commercial bakery, too much enzyme in the flour can affect the yield, as the dough needs less water. Premix formulations are developed and preprepared in bulk. Changing the premix recipe regularly can be expensive and impractical. Adjustment to proving times is not always possible as, in automated plants, the dough travels for a set time and distance through the proving cabinets. Sticky dough creates enormous challenges to automated bakery plants where closed high-speed mixers are used, dough is turned out for further processing and dough scaling is done mechanically. Inconsistent scaling weights and dough sticking to equipment causes delays in production and losses due to poor quality finished products.

In a home baking environment, on the other hand, it is easy to change the recipe and the process. More flour or less water can be used; the recipe is usually very simple with just a few ingredients and no enzymes or any other bread improvers are used; and the proving time can be controlled. For these reasons, better results can be expected from flour with high enzyme activity than in a commercial bakery.

The falling number test

The Hagberg Falling Number test is used to determine the alpha-amylase enzyme activity in wheat flour. During the test, a glass tube with a mixture of flour and water is heated up. The mixture thickens as the starch cooks and at the end of mixing, a steel plunger is released to drop through the cooked mixture. The time that the plunger takes to drop the length of the tube is recorded in seconds and the thicker the mixture, the longer it will take for the plunger to drop.

During this starch thickening process, the alpha-amylase enzymes break down the starch (in the same way as during baking, as explained above), therefore if a lot of enzyme is present, the starch will break down quickly and the mixture will be less thick and more liquid. That means that the plunger will drop through the mixture at a faster rate and give a low falling number result.

A low falling number (e.g. below 220 sec) indicates high enzyme activity, most often as a result of sprout damaged wheat or flour. A high falling number (e.g. above 300 sec) indicates very little enzyme activity and no sprouting. Usually, falling numbers over 250 are suitable for most breadmaking processes.

Too much alpha-amylase in cereals can be the result of mainly two reasons; one is pre-harvest sprouting, which is caused by poor weather conditions before harvest (usually heavy rainfall) causing the grain to sprout too early.

The second reason is called “late maturity alpha-amylase”, which is a genetic defect. Some wheat cultivars tend to have abnormally high levels of alphaamylase, which may be triggered by extreme temperatures (very cold or very hot) or cool conditions that carry on for a long time (Newberry et al., 2018). Genetics can further influence the falling number value, namely with regards to the starch composition in the flour. In flour, starch is made up of two types, namely amylose (about 22%) and amylopectin (about 78%).

If the starch in flour consists of mainly amylopectin, it is referred to as waxy. When water is added to starch and the mixture is heated up (as is described in the falling number test), the amylopectin will swell more than the amylose. That means that the cooked starch will be less dense, and the plunger will fall through it faster, giving a low falling number result, which in this case is because of the waxy starch and not the presence of the enzyme (Bettge, 2018).

Commercial bakeries invest a lot of time and money in optimising baking processes, such as preparation of the recipe and premix formulations, the amount of water that is added, mixing

and dividing the dough, baking and ultimately end product quality. It is important to be aware of the amount of enzyme activity in wheat flour, its relation to falling number, the factors that can affect the falling number and its effect on the baking quality of the flour.

The challenges posed in commercial baking with low falling numbers are difficult to solve and can cause large financial losses if introduced into the baking process, especially if the bakery is automated. It is possible for mills to use falling number information to blend wheat with different falling number values, in order to minimise the effect of for example sprouted wheat, by using a formula called a Liquefaction Number, but it is important to be aware of the limits to this method of blending.